Ensuring Flawless Execution: How HansaMatrix Guarantees Quality in Complex Electronics Manufacturing

Audris Lukasevics, Quality and New Product Introduction Manager (Photo: HansaMatrix)

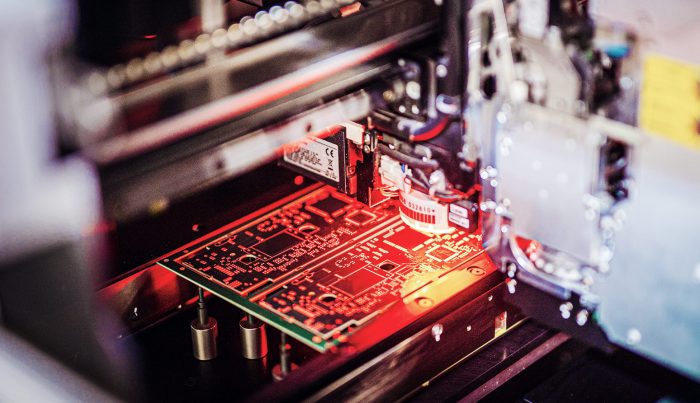

Imagine the pressure of assembling complex electronics – a crucial component for industrial machinery. Every connection, every component placement, hinges on flawless execution. For companies relying on these intricate parts, quality isn’t optional, it’s the lifeblood of their operations. In this interview, Audris Lukasevics, Quality and New Product Introduction Manager at HansaMatrix, unveils their meticulous quality control procedures, industry certifications, and commitment to continuous improvement – the hallmarks that ensure success in this high-wire act of electronics manufacturing.

Here’s a closer look at what you’ll learn in this article:

- HansaMatrix Expertise: Discover how their extensive experience translates to superior quality in complex electronics assembly.

- Deep Dive into Quality Control: Explore Hansamatrix.com’s robust quality control procedures, including meticulous traceability and their ERP system integration.

- The Power of Certifications: Understand how Hansamatrix.com’s certifications, like ISO 9001:2015 and IPC-A-610 certified trainers, build trust and confidence.

- Beyond Certifications: Best Practices Revealed: Learn about Hansamatrix.com’s commitment to best practices, including Lean manufacturing principles and Electrostatic Discharge (ESD) protection.

- Continuous Improvement: A Hallmark of Excellence: See how Hansamatrix.com stays ahead of the curve by continuously refining their quality control procedures.

Experience Breeds Expertise

HansaMatrix extensive experience positions them as a trusted partner for complex electronics assemblies. “With over 20 years in the industry,” says Audris, “we’ve developed a broad set of skills and know-how. Every product, regardless of complexity, undergoes the same rigorous processes, using the same advanced equipment and handled by our team of seasoned professionals.” This ensures consistency and quality across the board.

A Deep Dive into Quality Control

For quality-focused managers, understanding the specifics of quality control procedures is essential. Audris elaborates on HansaMatrix approach:

- Traceability: “We maintain meticulous traceability of every component, linking it to a specific product serial number and the original material packaging box. This ensures complete transparency throughout the manufacturing process.”

- ERP Integration: “Our robust ERP system controls product documentation from the very beginning, starting with the initial request for quotation (RFQ), all the way through procurement, warehousing, and manufacturing. This comprehensive system tracks everything with a full audit history, guaranteeing complete control.”

Certifications: Building Trust and Confidence

Industry certifications demonstrate a company’s commitment to quality. HansaMatrix holds a range of certifications that underscore their dedication to high standards:

- ISO 9001:2015: Quality Management System

- ISO 14001:2015: Environmental Management System

- ISO 13485:2016: Quality Management System for Medical Devices

- EN 9100:2016: Quality Management Systems – Requirements for Aviation, Space and Defense Organizations

- IPC-A-610 Certified Trainers: HansaMatrix has two in-house trainers qualified to certify personnel according to IPC-A-610 standards for electronics assembly acceptability.

“These certifications,” explains Audris, “translate to tangible benefits for our clients. They instill confidence in our integrated management system and the expertise of each employee. Furthermore, the continuous improvement processes implemented for demanding industries benefit all our customers.”

Beyond Certifications: Best Practices for Complex Assemblies

HansaMatrix goes beyond just meeting certification requirements. They actively employ best practices to ensure the highest quality in complex electronics assembly:

- Lean Manufacturing Principles: HansaMatrix incorporates Lean principles like LEAN, MTM (Methods-Time Measurement), and Theory of Constraints (TOC) to optimize production processes and eliminate waste.

- Electrostatic Discharge (ESD) Protection: “All our facilities are equipped with preventive ESD measures,” says Audris. “This includes special flooring, garments, and footwear. Additionally, all workstations, tools, and equipment are ESD-safe and regularly monitored to prevent potential damage to sensitive electronic components.”

Continuous Improvement: A Commitment to Excellence

In the ever-evolving world of electronics manufacturing, continuous improvement is key. “We embrace new challenges presented by our customers and their end-users,” emphasizes Audris. “By constantly learning and growing alongside our clients, we ensure our quality control procedures remain at the forefront of the industry.”

HansaMatrix unwavering commitment to quality, from their experienced staff and robust quality control procedures to their industry certifications and dedication to continuous improvement, positions them as a trusted partner for companies seeking flawless execution in complex electronics manufacturing.