Scaling Up with Agility: How HansaMatrix Partners with Tech Startups to Bring Innovative Products to Market

The fast-paced world of tech startups demands a unique approach to electronics manufacturing. Startups need a partner who can not only handle high-mix, low-volume production runs but also adapt to rapidly changing technology needs and frequent design iterations. In this interview, Jevgenijs Kostjukēvičs, Key Account Manager at HansaMatrix, discusses the challenges faced by startups and how HansaMatrix positions itself as a perfect fit for the dynamic world of tech innovation, particularly in the Internet of Things (IoT) and smart sensor space.

Brief overview of this article:

- The Obstacle Course of Startup Manufacturing: Discover the challenges faced by tech startups when it comes to electronics manufacturing, particularly regarding low-volume production and keeping pace with innovation.

- The HansaMatrix Advantage: Explore how HansaMatrix tackles these challenges through dedicated project teams, their extensive knowledge of electronics components, and a commitment to open communication.

- From Prototype to Market: A Success Story: Learn how HansaMatrix approach helped a startup streamline their journey from initial concept to product launch.

Finding the Right Fit: A Challenge for Startups

Finding the right electronics manufacturing services (EMS) partner is crucial for any startup’s success. However, as Jevgenijs highlights, it can be a challenge.

“The biggest challenge is to find the right synergy and a perfect fit EMS partner,” says Jevgenijs. “Lots of EMS allocate their time depending on a business scale. Since startups are unpredictable, not all manufacturers will put in a reasonable effort.”

HansaMatrix solves this problem by dedicating a special team to each project. This team, consisting of a key account manager, procurement specialist, and New Product Introduction (NPI) expert, leverages their combined experience to cater to the specific needs of each startup.

Adapting to Change: Keeping Pace with Innovation

The tech industry is characterized by rapid innovation and frequent design changes. HansaMatrix understands this and has built a system to ensure agility.

“HansaMatrix has a huge catalog of alternative part numbers and electronic component suppliers,” explains Jevgenijs. “Very often, we suggest our clients change the Bill of Materials (BOM) or layout, since our suppliers keep us informed about the latest components available. And yes, a dedicated team is key for agile support.”

This deep knowledge of the electronics component landscape allows HansaMatrix to propose alternative components when necessary, potentially reducing costs and lead times. Open communication is another key aspect of their approach.

“Each project has its own communication approach,” says Jevgenijs. “Nevertheless, HansaMatrix will develop an action plan to track the project’s progress. Our doors are always open, and we welcome guests at our facilities.”

Making Low-Volume Production Work

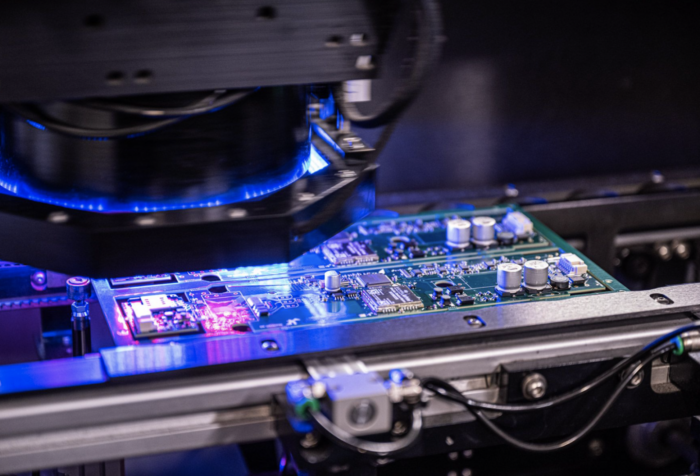

High-mix, low-volume production runs are a common reality for startups. HansaMatrix tackles this challenge by utilizing their two production plants, which share the same equipment and Enterprise Resource Planning (ERP) system.

“Using both plants with the same equipment and ERP system, we can easily find a slot and manage low-volume runs,” explains Jevgenijs. “This approach helps us deliver on time and ensures a fast ramp-up.”

While confidentiality agreements prevent Jevgenijs from sharing specific client names, he assures us that HansaMatrix consistently works with 2-3 startups at each plant, demonstrating their expertise in handling low-volume production needs.

Success Story: From Prototype to Market

Jevgenijs offered a glimpse into a successful partnership with a startup, highlighting how HansaMatrix’s approach helped them navigate the challenges of bringing their product to market.

“We started working with a client in 2017 who only had a raw BOM and Gerber files,” says Jevgenijs. “Based on our experience, we suggested changes to the layout, component selection, and suppliers. As a result, we were able to reduce BOM costs, lead times, and ensure a faster ramp-up.”

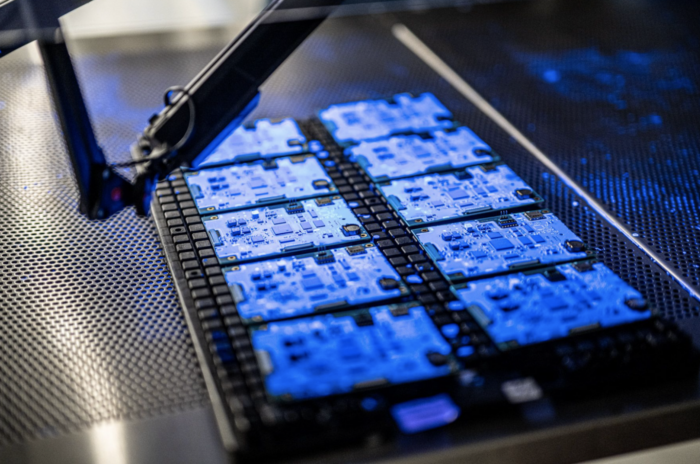

Following the initial prototype runs, HansaMatrix implemented a PCBA buffer stock strategy, allowing for increased batch sizes and further cost reduction. This strategy ultimately ensured the fastest possible time to market for the startup’s innovative product.

Conclusion

HansaMatrix commitment to agility, expertise in low-volume production, and open communication make them a valuable partner for tech startups in the connectivity sector. Their ability to adapt to changing needs and leverage their knowledge of the electronics component landscape positions them as a perfect fit for companies seeking to bring their innovative ideas to life.