The global electronics manufacturing landscape is undergoing a significant shift. Companies are increasingly seeking to diversify their supply chains to mitigate risk and optimize costs. In this interview, Andrius Luinys, Chief Business Development Officer at HansaMatrix, a leading Electronics Manufacturing Services (EMS) provider in Baltics and Eastern Europe, discusses the key drivers behind supply chain diversification and how HansaMatrix positions itself as a reliable partner in this evolving environment.

The Need for Diversification: Balancing Risk and Opportunity

Andrius highlights two main factors driving the trend towards supply chain diversification:

- Risk Mitigation: Overdependence on a single source supplier can be detrimental. “There’s a need to have at least a double source (in some cases even multi-source) supply scenario,” says Andrius. This ensures continuity if a supplier encounters disruptions like “force majeure issues, low capacity, or technical problems.”

- Cost Control and Optimization: Diversification allows companies to leverage competition among EMS providers. “Original equipment manufacturer (OEM) companies can split their total yearly electronic manufacturing need” based on factors like cost, volume, and technical requirements. This allows them to identify the “best possible suppliers for their needs.”

The recent COVID-19 pandemic further emphasized the importance of diversification. Pre-pandemic, “nearshoring” – manufacturing closer to home – was a less popular option. However, “unpredictable local governmental measures” and logistical challenges in Asia during the pandemic highlighted the benefits of geographically diverse supply chains. HansaMatrix, with its facilities in Latvia, is well-positioned to support companies seeking nearshoring solutions.

Expertise for Diverse Needs: A Wealth of Experience

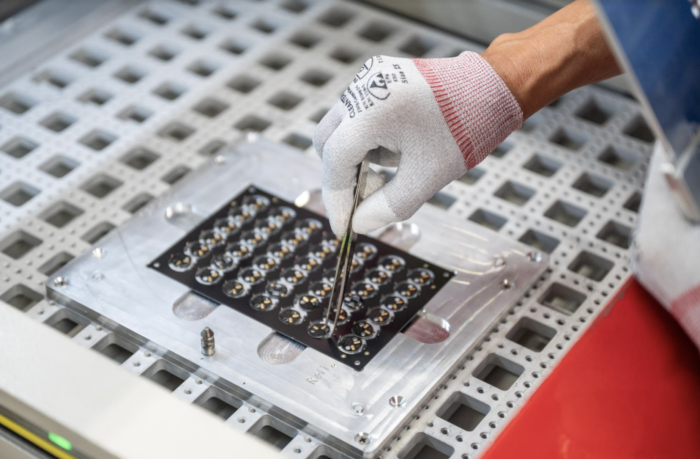

With a 25-year track record, HansaMatrix boasts extensive experience in manufacturing a wide variety of electronic products across multiple sectors. They are a mid-sized company with a team of roughly 500 employees working across four manufacturing sites, primarily serving customers in the Baltics and Eastern Europe. “We focus on Connectivity, Industry and Energy sectors,” says Andrius, “and are involved in applications such as data network devices, optics, IoT devices, hearing protection, machine vision cameras and much more.”

This diverse experience allows HansaMatrix to develop a deep understanding of different technical requirements. Their New Product Introduction (NPI) process includes design reviews for clients, “to adjust design for serial manufacturing for better efficiency, higher first past yield, and smoother production processes.”

One example Andrius shares is the complex underwater cameras they manufacture for the aquaculture sector. These cameras require a high degree of precision and incorporate a variety of built-in sensors. HansaMatrix manufactures the most complex mechanical parts in-house and performs the final assembly and optical testing.

Reliability and Standards: Guaranteeing Quality and On-Time Delivery

For companies diversifying their supply chains, trust in a new EMS provider is paramount. HansaMatrix emphasizes their commitment to quality and on-time delivery through several key practices:

- Industry Certifications: Their adherence to international quality standards like ISO 9001, ISO 13485, AS 9100, and ISO 14001 demonstrates their dedication to quality management.

- In-House Manufacturing Execution System: HansaMatrix leverages their 25 years of experience to create a robust Manufacturing Execution System (MES) tailored to each client’s specific needs.

Building Trust and Long-Term Partnerships: Transparency and Communication

Building strong, long-term partnerships requires trust and open communication. HansaMatrix prioritizes these aspects in their client relationships.

- Customer-Centric Culture: “We see our customers as partners,” explains Andrius. “Our company culture is customer centric.” They gather regular customer feedback and focus on continuous improvement to maintain high satisfaction levels.

- Dedicated Customer Teams: Each client is assigned a dedicated team that supports their product manufacturing on a daily basis, ensuring clear and efficient communication across all levels.

- Transparency and Openness: “Trust is one of our key values,” says Andrius. “We try to be as open as much as possible with our customers.” This level of transparency fosters strong and lasting partnerships.

HansaMatrix: An EMS+ Provider with a Lean Structure and Free Capacity

Beyond the core EMS services, HansaMatrix positions itself as an EMS+ provider, offering additional value-added services to their clients. Andrius elaborates: “We are capable of manufacturing Printed Circuit Boards Assembly (PCBA), metal and plastic mechanical parts and doing final assembly of the product. So, in practice our customers do not need to have 5 different suppliers – HansaMatrix can cover all the needs.”

The Future of Electronics Manufacturing: A Forward-Thinking Approach

HansaMatrix recognizes the importance of flexibility and adaptability in the ever-changing world of electronics manufacturing. Their ability to “adapt to changing technology requirements” and provide “flexible engineering support” will be crucial for success. They are also prepared to accommodate “immediate acceleration in production volumes” as new technologies emerge.

Conclusion

In conclusion, HansaMatrix presents a compelling proposition for companies seeking a reliable and experienced partner to navigate the complexities of supply chain diversification. Their commitment to quality, diverse expertise, open communication, and a forward-thinking approach position them as a valuable asset for companies in the evolving electronics manufacturing landscape.